Ukukhiqiza ingilazi kuyinqubo edinga amandla amaningi, cishe amaphesenti angama-75 kuya kwangu-85 wamandla asetshenziswa ngesikhathi sokuncibilika kwengilazi.Ukunciphisa ukusetshenziswa kwamandla kunoma yisiphi isigaba sokukhiqiza ingilazi kungaba yinzuzo ngezindlela ezimbili: okokuqala, njengoba amandla ebiza kakhulu ekusetshenzisweni kwenqubo yokukhiqiza, ukonga amandla kungaholela ekongeni okuqondile;Okwesibili, enqubweni yokukhiqiza, ukusetshenziswa okuphezulu kokushisa okushisayo, ukulawula okunembe kakhudlwana kwe-viscosity yoketshezi lwengilazi oluncibilikisiwe.Lokhu kwenza ukulawulwa kwekhwalithi yomkhiqizo kube lula, okuholela ekongeni kwezindleko eziqondile ngokunciphisa udoti.Ngakho-ke ama-refractories asebenzayo futhiizinto zokushisa ezishisayoziya ngokuya zibaluleke kakhulu emishinini yokwenza ingilazi.Esikhathini esidlule, izikhonkwane zengilazi zazisetshenziswa kakhulu izinto zokufudumeza ezishisayo, kodwa ngokuvamile zinokushisa okuphezulu kwe-thermal conductivity, umphumela wokonga amandla awulungile.Ngokukhula kwesidingo sokonga amandla, uhlobo oluthile lwe-microporous insulation material lusetshenziswa kakhulu ekukhiqizeni ingilazi.

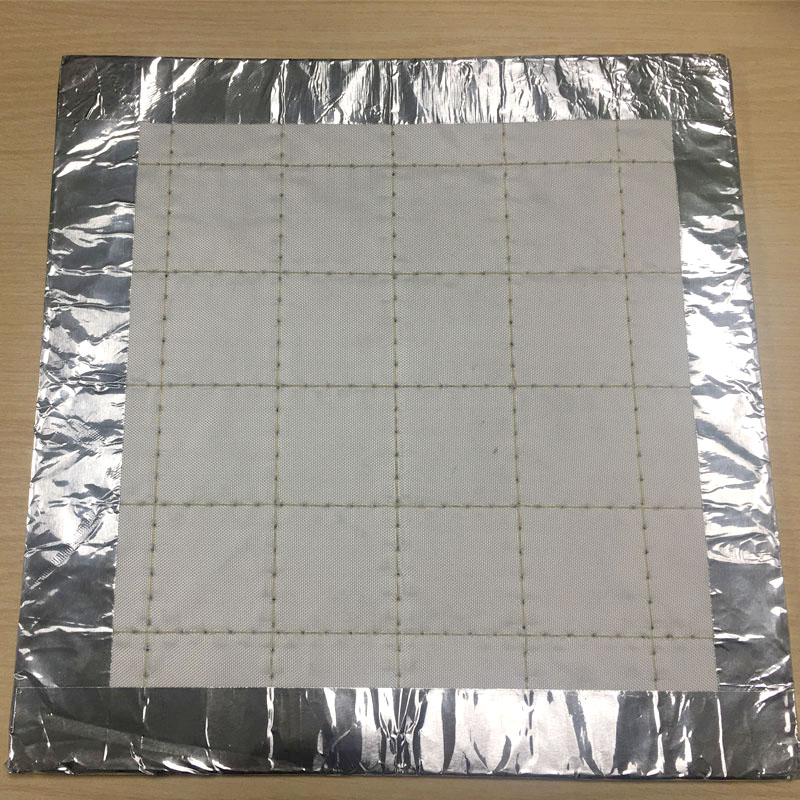

I-Microporous Insulation iphrofayili entsha eyenziwe ngokususelwa kumgomo wokufakwa kwe-microporous.Izingxenye eziyinhloko yi-ultrafine silicon oxide powder enobubanzi obuyi-7 kuya ku-12 nanometers, izinto zokuvikela emisebeni eshisayo exubile, futhi icindezelwe ubuchwepheshe obukhethekile.Ubuso bomkhiqizo bungambozwa ngendwangu yengilazi ye-fiber, amafomu avamile ayizinhlobo eziyisicaba, uhlobo lokugoqa.Uhlobo lwebhulokhi, uhlobo lwengubo ethambile, njll. Uhlobo oluyisicaba lungasetshenziselwa udonga lwesithando somlilo noma udonga olukhulu lwesithando somlilo olugobile, uhlobo lokugoqa lusetshenziselwa ikakhulukazi uhlelo lwamapayipi.Enkambweni yokukhiqiza ingilazi, umsebenzi oyinhloko wepuleti ye-insulating microporous ukunciphisa ukulahlekelwa ukushisa.Yehlisa ukusetshenziswa kwamandla: thuthukisa indawo yokusebenza kwefekthri;Ukwandisa impilo yemishini yokunciphisa ukushuba kwesendlalelo sokushisa ukushisa, ukunciphisa umthamo wemishini;Khulisa ivolumu yangaphakathi.Yehlisa ukugcinwa kokushisa kongqimba lwe-insulation futhi ukhuphule izinga lokushisa

Ukulahlekelwa ukushisa kudinga ukulawulwa ngokucophelela kuyo yonke inqubo yokwenza ingilazi ukuze kuqinisekiswe ukusebenza kahle kwamandla kanye nomthelela omncane wendawo.Indlela ephumelela kakhulu yokugcina ukushisa ukusebenzisa i-microporous adiabatic system, enezinzuzo ezilandelayo:

I-conductivity ephansi kakhulu yokushisa, ukusebenza kahle kwayo kwe-adiabatic yizinto zendabuko ze-adiabatic ezinyakazayo izikhathi eziningana

I-conductivity ephansi kakhulu yokushisa, ukusebenza kahle kwayo kwe-adiabatic yizinto zendabuko ze-adiabatic ezinyakazayo izikhathi eziningana

Ingasetshenziswa ekukhiqizeni imikhiqizo ehlukahlukene ngemikhiqizo eyenziwe ngaphambili, futhi ingakhiwa ngaphambili noma isikwe kalula futhi ilungiswe endaweni yokufaka.

Isistimu ye-adiabatic thinnest, elula kunazo zonke.Ugqinsi lwesistimu yokufaka i-insulation yingxenye yesine kuphela yogqinsi lwento evamile yokugqumisa

Ayikho i-fiber ehogeliwe, ayinabungozi ngokuphelele, ihambisana nemvelo.Kuphephile futhi kuhlanzekile ukusebenzisa, ngokuhambisana nokuphepha kwamazwe ngamazwe kanye nezinkambiso zezempilo

Iyakwazi ukusebenza ngokuqhubekayo nokuzinzile ku-800 °C -1000°C.Ngokuncipha komugqa okunganaki kumazinga okushisa aphezulu, ukusebenza kahle kokugaya kabusha, akukho monakalo.

Ngenxa yokuvuthwa okuqhubekayo kobuchwepheshe bokusebenzisa i-nano microporous heat insulation materials, ukusetshenziswa okuphumelelayo kwezinye izimboni zezingilazi eminyakeni yamuva nje kufakazele ukuthi izinto ezisetshenziswayo zinomthelela omangalisayo ekongeni amandla kanye nokwehliswa kokukhishwa kwezinto ezikhishwayo.Nakuba kuqhathaniswa nezinto ezivamile zokuvikela ukushisa, izindleko zokuqala zokutshala zizokwenyuswa ngezinga elithile, kodwa ukuncishiswa kwakamuva kwenzuzo yokusetshenziswa kwamandla kubalulekile, uma kucatshangelwa izinzuzo zesikhathi eside ezilethwa ukongiwa kwamandla kanye nokunciphisa ukukhishwa kwe-emission, ukutshalwa kwezimali okunjalo kuyafaneleka.Kuyaqapheleka ukuthi ngaphansi kwesizinda sezidingo ezikhulayo zokongiwa kwamandla kanye nokunciphisa ukukhishwa kwe-emissions, ukusetshenziswa kwezinto zokufaka ukushisa kwe-nano-porous embonini yengilazi kuzothandwa kakhulu.

I-Zerothermo sigxile kubuchwepheshe be-vacuum iminyaka engaphezu kwengu-20, imikhiqizo yethu eyinhloko: amaphaneli okufakwa kwe-vacuum asekelwe ezintweni eziyinhloko ze-silica zomuthi wokugoma, ukwelashwa, okokusebenza kweketango elibandayo, ifriji, i-vacuum insulation ehlanganisiwe nephaneli yokuhlobisa,vacuum glass, vacue iminyango namafasitela avalelwe.Uma ufuna ukufunda ulwazi olwengeziwe mayelana Amaphaneli e-Zerothermo vacuum insulation,sicela ukhululeke ukuxhumana nathi, futhi wamukelekile ukuvakashela efektri yethu.

Umphathi Wokuthengisa: UMike Xu

Ucingo: +86 13378245612/13880795380

E-mail:mike@zerothermo.com

Iwebhusayithi:https://www.zerothermovip.com

Isikhathi sokuthumela: Feb-23-2023